VY10 550

Technical Characteristics

- Rated input power: Single phase 220V

- Input power frequency: 50/60 Hz

- Laser Power: 1500 W

- Rated Input Power: 5400 W

- Welding Speed: 20-200 cm/min

- Cooling Mode: Dual circuit refrigerant direct cooling

- Working temperature: –20 to 60 °C

- Storage temperature: –40 to 85 °C

- Working humidity: 0–90 %

- Product dimensions: 673 × 310 × 605 mm

- Product weight: 45 kg

- Applicable wire diameter: 0.8 / 1.0 / 1.2 / 1.6 / 2.0 mm

- Armored Cable Length: 5 / 10 / 15 / 20 m (customizable)

- Welding Mode: Spot welding / Continuous spot welding / Pulse welding / Continuous welding

Comparison Of Laser Welding And Traditional Welding (TIG/MIG)

Here is a comparison table between Laser Welding and Traditional Welding (TIG/MIG) to help you understand the differences in terms of key aspects such as precision, cost, and efficiency:

| Aspect | Laser Welding | Traditional Welding (TIG/MIG) |

|---|---|---|

| Heat Input | Very low, minimal thermal distortion | High, large heat-affected zone |

| Precision | Extremely high thanks to small spot size | Good but limited |

| Processing Speed | Very high | Moderate |

| Initial Investment | Higher | Low |

| Operating Costs | Lower long-term (no filler, high efficiency) | Low to moderate |

| Material Thickness | Best for thin to medium thickness | Ideal for medium–thick materials |

| Geometry Flexibility | Excellent for intricate, fine geometries | Limited with very small or complex shapes |

| Aesthetic Result | Clean, sharp, minimal weld seams | Visible weld seams |

| Automation | Requires advanced automation systems | Easier and cheaper to automate |

| Sustainability | More energy-efficient and sustainable | Higher heat and energy usage |

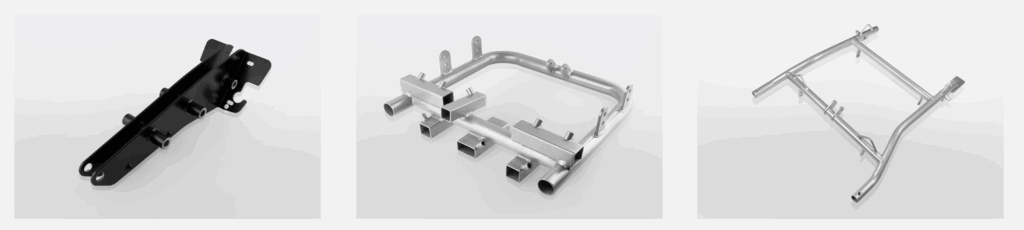

Application

Laser welding is suitable for a wide range of materials, including titanium, nickel, tin, zinc, copper, aluminum, chromium, niobium, gold, silver, and many other metals and alloys such as steel and Kovar. It can also join different types of metals—for example, copper to nickel, nickel to titanium, titanium to molybdenum, brass to copper, and low-carbon steel to copper.

Ready to help

Ready to Work Together? Get in touch!

Learn More From

Frequently Asked Questions

Yes. Laser welding typically uses shielding gases such as nitrogen or argon. These gases protect the molten weld pool from atmospheric contamination and improve overall weld quality. Using the correct gas is essential for achieving stable, precise, and high-quality welds.

Handheld fiber laser welding machines are highly versatile and compatible with a wide range of metals. They are especially effective for materials like stainless steel, carbon steel, and aluminum. Their precision and control make them ideal for producing clean, strong welds across various metal types.

Yes. Laser welding—particularly with handheld fiber systems—can match or exceed the strength of traditional arc welds. It offers higher efficiency, often more than triple that of conventional welding, and produces cleaner, more accurate results.

The welding capacity depends on the machine’s power rating. Here are the general guidelines:

1000W: Welds carbon steel and stainless steel up to 3 mm; aluminum up to 2 mm.

1500W: Welds carbon steel and stainless steel up to 4 mm; aluminum up to 2.5 mm.

2000W: Handles carbon steel and stainless steel up to 5 mm; aluminum up to 3.5 mm.

3000W: Suitable for carbon steel and stainless steel up to 7 mm; aluminum up to 5 mm.

3000W dual-sided welding: Capable of welding carbon steel and stainless steel up to 15 mm; aluminum up to 10 mm.

The machine can weld seams of various sizes, but when the gap exceeds 1 mm, filler wire is typically required to ensure proper joint filling. The weld seam should not be wider than the diameter of the welding wire, which sets the upper limit for acceptable seam size.

This multifunctional system combines four key capabilities in a single device: laser welding, laser cutting, weld-seam cleaning, and surface laser cleaning, making it a highly efficient and adaptable tool for metal fabrication tasks.

Get A Quote

Please let us know more specific information regarding your future project.