VY20 S W1

Technical Characteristics

- Laser type: Fiber Laser

- Max laser power: 1000W

- Center wavelength: 1064nm±10

- Laser source: Raycus/Max/BWT optional

- Modulation frequency (Hz): 1-20000

- Output Power: 0.5-1mm

- Fiber Cable Length: 10m

- Fiber Core Diameter: 50μm

- Wire Feeder: Single and double

- Total Power Consumption: 7.5kW

- Rated Power: 220±10%V AC, 50/60Hz

- Cooling Method: Water Cooling

- Gross / Net Weight: 230 / 180 kg

- Machine Dimensions (L*W*H): 850*650*1035 mm

- Packing Dimensions (L*W*H): 1290*780*1190 mm

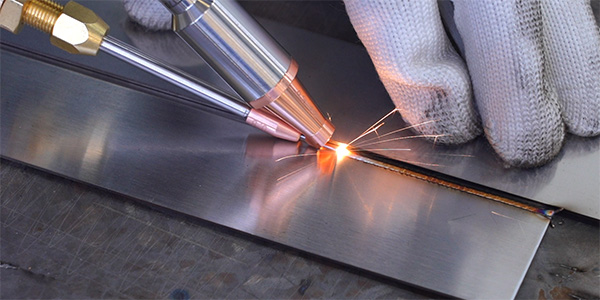

Laser Welding Stainless Steel

Laser Welding Copper

Laser Welding Aluminum Alloy

4-in-1 Handheld Fiber Laser Welding Machine

Welding • Cutting • Cleaning • Weld Seam Cleaning

The 4-in-1 handheld fiber laser welding machine integrates a high-performance fiber laser source, ergonomic handheld laser gun, water chiller, and an intelligent all-in-one control system. Designed for welding, cutting, surface cleaning, and weld seam cleaning, this versatile solution streamlines multiple metalworking processes into a single compact unit.

Compatible with leading fiber laser brands, the system features an optimized optical path and efficient water-cooling design, ensuring stable, continuous operation at power levels up to 3000W. The handheld laser gun enables precise metal welding and cutting, while effectively removing weld residue, rust, paint, coatings, oil, resin, and other surface contaminants.

By combining weld cleaning with traditional laser functions, this user-friendly system eliminates the need to invest in multiple machines. Whether joining metal components, executing precision cuts, or preparing and finishing welds, this all-in-one laser solution delivers exceptional efficiency and flexibility.

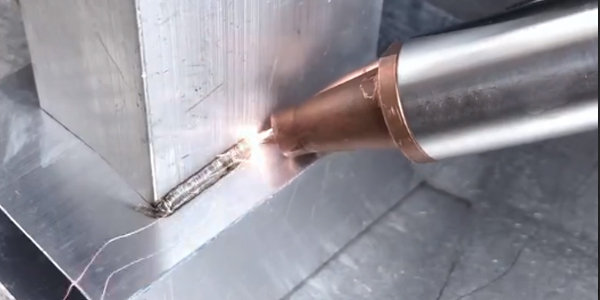

Laser Welding

This fiber laser welder provides high-precision welding for a wide range of metals, including steel, aluminum, and copper. Its high-power output ensures fast, accurate welds with smooth, visually appealing seams—often eliminating the need for secondary grinding or post-processing.

The system is easy to learn and operate, delivering consistent, high-quality results across various material thicknesses. Its high-speed welding capability significantly boosts productivity.

Equipped with advanced 5-in-1 welding modes—spot welding, seam welding, pulse welding, continuous welding, and repair welding—the machine adapts to diverse application requirements.

Laser Cleaning

The laser cleaning function offers a non-abrasive, environmentally friendly method for removing rust, paint, oxides, and other contaminants. It cleans efficiently without damaging the base material, making it ideal for surface preparation and maintenance.

Laser Cutting

In addition to welding and cleaning, the machine supports precision laser cutting. By concentrating high-energy laser beams, it can accurately cut metals, plastics, and composite materials with clean edges and minimal distortion.

Weld Seam Cleaning

After welding, the system can remove spatter, oxidation, and residue from the weld area. This ensures a clean weld path, improves appearance, and prepares the surface for additional welding passes or finishing processes.

All-in-One Performance

The 4-in-1 handheld fiber laser welder seamlessly combines laser welding, cutting, surface cleaning, and weld seam cleaning. It efficiently removes oil, rust, and coatings before welding and cleans debris and weld seams afterward—while also handling various sheet metal cutting tasks. This multifunctional design helps users maximize productivity and adapt to a wide range of working conditions.

Handheld Laser Gun

The compact handheld laser gun supports welding, cutting, cleaning, and weld seam cleaning through an intelligent control system. Lightweight and portable, it enables flexible operation with low running costs and no consumables required.

Mobile operation: 10-meter fiber optic cable for extended reach

Quick function switching: Easily change from welding to cleaning by replacing the focusing lens and laser head

Key Components & Features

Fiber Laser Generator Options: Compatible with premium brands such as Ruike, MAX, and IPG, offering high photoelectric conversion efficiency, low energy consumption, maintenance-free operation, and compact design.

Built-in Cooling System: Integrated cooling eliminates external wiring, enhances portability, and provides excellent dust protection.

Intelligent Control Panel: One-touch start and intuitive parameter adjustment ensure simple, efficient operation.

Key Advantages

Portable design: Compact and lightweight for easy transport and on-site operation

Multifunction capability: Welding, cutting, cleaning, and weld seam cleaning in one system

High precision: Produces clean, accurate, and aesthetically pleasing welds

Wide material compatibility: Suitable for stainless steel, aluminum, copper, brass, titanium, and more

User-friendly interface: Simple controls for quick setup and adjustments

Enhanced safety: Built-in safety features protect both operator and equipment

Advanced Laser Technology

Designed for efficiency and ease of use, this handheld fiber laser welding machine delivers faster, cleaner, and more precise results than traditional TIG or MIG welding—making it an ideal solution for modern metal fabrication.

| Laser Type | Fiber Laser |

| Max Laser Power | 1000 W |

| Center Wavelength | 1064 nm ± 10 |

| Laser Source | Raycus / Max / BWT |

| Modulation Frequency | 1-20000 Hz |

| Output Power | 0,5-1 mm |

| Fiber Cable Length | 10 m |

| Fiber Core Diameter | 50 μm |

| Wire Feeder | Single and double |

| Total Power Consumption | 7.5 kW |

| Rated Power | 220 ± 10 V AC, 50/60 Hz |

| Cooling Method | Water Cooling |

| Gross / Net Weight | 230 / 180 kg |

| Machine Dimensions (L*W*H) | 850*650*1035 |

| Packing Dimensions (L*W*H) | 1290*780*1190 |

Metal Welding Parameters

| Material | Gas used | Thickness(mm) | Laser power(W) | Wire diameter(mm) | Wire speed(mm/s) | Scanning speed(mm/s) | Scan width(mm) | Welding frequency(HZ) | Duty cycle | Barometric pressure(bar) |

| Stainless steel | Argon | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000 | 100 | 10 |

| 1.5 | 1000 | 1 | 90 | 300 | 2.5 | 1000 | 100 | 10 | ||

| 2 | 1500 | 1.2 | 75 | 300 | 3 | 1000 | 100 | 10 | ||

| 2.5 | 2000 | 1.2 | 75 | 300 | 3 | 1000 | 100 | 10 | ||

| 3 | 2000 | 1.6 | 60 | 300 | 3.5 | 1000 | 100 | 10 | ||

| 4 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000 | 100 | 10 | ||

| Carbon steel | Argon | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000 | 100 | 10 |

| 1.5 | 1000 | 1 | 90 | 300 | 2.5 | 1000 | 100 | 10 | ||

| 2 | 1500 | 1.2 | 75 | 300 | 3 | 1000 | 100 | 10 | ||

| 2.5 | 2000 | 1.2 | 75 | 300 | 3 | 1000 | 100 | 10 | ||

| 3 | 2000 | 1.6 | 60 | 300 | 3.5 | 1000 | 100 | 10 | ||

| 4 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000 | 100 | 10 | ||

| Galvanized sheet | Argon | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000 | 100 | 10 |

| 1.5 | 1500 | 1 | 90 | 300 | 2.5 | 1000 | 100 | 10 | ||

| 2 | 2000 | 1.2 | 75 | 300 | 2.5 | 1000 | 100 | 10 | ||

| 2.5 | 2000 | 1.6 | 60 | 300 | 3 | 1000 | 100 | 10 | ||

| 3 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000 | 100 | 10 | ||

| Aluminum | Nitrogen(N2) | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000 | 100 | 10 |

| 1.5 | 1500 | 1 | 90 | 300 | 2.5 | 1000 | 100 | 10 | ||

| 2 | 2000 | 1.2 | 75 | 300 | 2.5 | 1000 | 100 | 10 | ||

| 2.5 | 2000 | 1.6 | 60 | 300 | 3 | 1000 | 100 | 10 | ||

| 3 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000 | 100 | 10 |

Does the laser welding machine require shielding gas?

Yes. Laser welding typically uses shielding gases such as nitrogen or argon to protect the molten metal from oxidation during the welding process. These gases help ensure stable welding performance, improved weld quality, and precise results.

What types of metals can be welded with the laser welding machine?

Handheld fiber laser welding machines are suitable for a wide range of metals, including stainless steel, carbon steel, and aluminum. Thanks to their high precision and energy control, they produce clean, strong, and consistent welds across various metal materials.

Is laser welding as strong as traditional arc welding?

Yes. Laser welding can achieve weld strength comparable to arc welding while offering significantly higher efficiency—often more than three times faster. It also delivers superior accuracy, minimal heat distortion, and cleaner weld seams.

How do I select the appropriate laser power for different material thicknesses?

Welding capacity depends on laser power. Our handheld laser welding machines support the following thickness ranges:

1000W: Carbon steel & stainless steel up to 3mm; aluminum up to 2mm

1500W: Carbon steel & stainless steel up to 4mm; aluminum up to 2.5mm

2000W: Carbon steel & stainless steel up to 5mm; aluminum up to 3.5mm

3000W: Carbon steel & stainless steel up to 7mm; aluminum up to 5mm

3000W double-sided welding:

Capable of welding carbon steel and stainless steel up to 15mm, and aluminum up to 10mm.

What weld seam sizes can the handheld laser welder handle, and is filler wire required?

The machine can weld various seam sizes. When the seam width exceeds 1mm, filler wire is generally required to properly fill the joint. The weld seam size should not exceed the diameter of the welding wire, as this determines the maximum fill capacity.

What functions are included in the 4-in-1 handheld laser welding machine?

The 4-in-1 handheld laser welding machine combines laser welding, laser cutting, weld seam cleaning, and laser surface cleaning into a single, efficient system—offering a versatile and cost-effective solution for modern metal fabrication.

Comparison Of Laser Welding And Traditional Welding (TIG/MIG)

Here is a comparison table between Laser Welding and Traditional Welding (TIG/MIG) to help you understand the differences in terms of key aspects such as precision, cost, and efficiency:

| Aspect | Laser Welding | Traditional Welding (TIG/MIG) |

|---|---|---|

| Heat Input | Very low, minimal thermal distortion | High, large heat-affected zone |

| Precision | Extremely high thanks to small spot size | Good but limited |

| Processing Speed | Very high | Moderate |

| Initial Investment | Higher | Low |

| Operating Costs | Lower long-term (no filler, high efficiency) | Low to moderate |

| Material Thickness | Best for thin to medium thickness | Ideal for medium–thick materials |

| Geometry Flexibility | Excellent for intricate, fine geometries | Limited with very small or complex shapes |

| Aesthetic Result | Clean, sharp, minimal weld seams | Visible weld seams |

| Automation | Requires advanced automation systems | Easier and cheaper to automate |

| Sustainability | More energy-efficient and sustainable | Higher heat and energy usage |

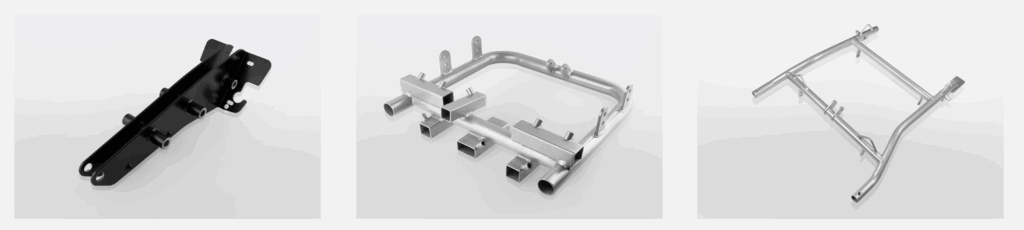

Application

Laser welding is suitable for a wide range of materials, including titanium, nickel, tin, zinc, copper, aluminum, chromium, niobium, gold, silver, and many other metals and alloys such as steel and Kovar. It can also join different types of metals—for example, copper to nickel, nickel to titanium, titanium to molybdenum, brass to copper, and low-carbon steel to copper.

Ready to help

Ready to Work Together? Get in touch!

Learn More From

Frequently Asked Questions

Yes. Laser welding typically uses shielding gases such as nitrogen or argon. These gases protect the molten weld pool from atmospheric contamination and improve overall weld quality. Using the correct gas is essential for achieving stable, precise, and high-quality welds.

Handheld fiber laser welding machines are highly versatile and compatible with a wide range of metals. They are especially effective for materials like stainless steel, carbon steel, and aluminum. Their precision and control make them ideal for producing clean, strong welds across various metal types.

Yes. Laser welding—particularly with handheld fiber systems—can match or exceed the strength of traditional arc welds. It offers higher efficiency, often more than triple that of conventional welding, and produces cleaner, more accurate results.

The welding capacity depends on the machine’s power rating. Here are the general guidelines:

1000W: Welds carbon steel and stainless steel up to 3 mm; aluminum up to 2 mm.

1500W: Welds carbon steel and stainless steel up to 4 mm; aluminum up to 2.5 mm.

2000W: Handles carbon steel and stainless steel up to 5 mm; aluminum up to 3.5 mm.

3000W: Suitable for carbon steel and stainless steel up to 7 mm; aluminum up to 5 mm.

3000W dual-sided welding: Capable of welding carbon steel and stainless steel up to 15 mm; aluminum up to 10 mm.

The machine can weld seams of various sizes, but when the gap exceeds 1 mm, filler wire is typically required to ensure proper joint filling. The weld seam should not be wider than the diameter of the welding wire, which sets the upper limit for acceptable seam size.

This multifunctional system combines four key capabilities in a single device: laser welding, laser cutting, weld-seam cleaning, and surface laser cleaning, making it a highly efficient and adaptable tool for metal fabrication tasks.